Gold-Tech Factory Monitoring OS

Gold-Tech Factory Monitoring OS

Gold-Tech Factory Monitoring OS

I designed an IoT-powered ecosystem that gives factory owners real-time visibility, reduces downtime, and improves overall operational health.

I designed an IoT-powered ecosystem that

gives factory owners real-time visibility,

reduces downtime, and improves overall operational health.

I designed an IoT-powered ecosystem that gives factory owners real-time visibility, reduces downtime, and improves overall operational health.

Service

Web App Industrial IoT

Web App Industrial IoT

Client

Gold Tech

Gold Tech

What I Do

Web Dashboard, Mobile

Web Dashboard, Mobile

Product Design

IOT Design

03 Figma

Factory App

Sass Platform

Product Design

IOT Design

03 Figma

Factory App

Sass Platform

Product Design

IOT Design

03 Figma

Factory App

Sass Platform

About this project

About this project

About this project

Gold-Tech Factory OS is a real-time monitoring platform built for manufacturing industries. It enables operators, supervisors, and plant managers to track machine performance, respond to alerts, and make data-driven decisions — all in a single unified system.

Gold-Tech Factory OS is a real-time monitoring platform built for manufacturing industries. It enables operators, supervisors, and plant managers to track machine performance, respond to alerts, and make data-driven decisions — all in a single unified system.

Gold-Tech Factory OS is a real-time monitoring platform built for manufacturing industries. It enables operators, supervisors, and plant managers to track machine performance, respond to alerts, and make data-driven decisions — all in a single unified system.

Problem

Factories rely on scattered tools, manual logs, and outdated dashboards. Users juggle between screens to understand machine health, task assignments, downtime reasons, and shift performance.

Factories rely on scattered tools, manual logs, and outdated dashboards. Users juggle between screens to understand machine health, task assignments, downtime reasons, and shift performance.

Factories rely on scattered tools, manual logs, and outdated dashboards. Users juggle between screens to understand machine health, task assignments, downtime reasons, and shift performance.

Solution

Gold-Tech unifies real-time monitoring, predictive alerts, and technician workflows into one clean IoT platform. It turns reactive maintenance into proactive insights, reducing downtime and improving operational efficiency.

Gold-Tech unifies real-time monitoring, predictive alerts, and technician workflows into one clean IoT platform. It turns reactive maintenance into proactive insights, reducing downtime and improving operational efficiency.

Gold-Tech unifies real-time monitoring, predictive alerts, and technician workflows into one clean IoT platform. It turns reactive maintenance into proactive insights, reducing downtime and improving operational efficiency.

Impact

The goal of the Gold-Tech Factory Monitoring OS project was to create a user-centered, intuitive system that allows operators and supervisors to monitor machines efficiently, respond quickly to alerts, and make informed decisions to reduce downtime and improve productivity.

The goal of the Gold-Tech Factory Monitoring OS project was to create a user-centered, intuitive system that allows operators and supervisors to monitor machines efficiently, respond quickly to alerts, and make informed decisions to reduce downtime and improve productivity.

The goal of the Gold-Tech Factory Monitoring OS project was to create a user-centered, intuitive system that allows operators and supervisors to monitor machines efficiently, respond quickly to alerts, and make informed decisions to reduce downtime and improve productivity.

Team

Client

Me (UX Designer)

Product Manager, Engineers

My role

Lead UI/UX Designer

Tools

Figma, Notion, FigJam, AI Tools

Timeline

4-5 week

The Challenges:

The Challenges:

The Challenges:

Operators struggled with alert noise and had to switch between multiple screens to complete basic tasks.

Operators struggled with alert noise and had to switch between multiple screens to complete basic tasks.

Supervisors lacked consolidated insights for shift planning and performance tracking.

Supervisors lacked consolidated insights for shift planning and performance tracking.

Leadership needed a scalable, modular UI that could expand with new sensors and IoT devices.

Leadership needed a scalable, modular UI that could expand with

new sensors and IoT devices.

The approach:

The approach:

The approach:

Human‑Centered Architecture

Human‑Centered Architecture

Designed clear workflows for operators and supervisors based on interviews and day‑in‑the‑life shadowing.

Designed clear workflows for operators and supervisors based on interviews and day‑in‑the‑life shadowing.

Calm, Industrial‑Friendly UI

Calm, Industrial‑Friendly UI

Soft tones, clean grids, and clear alert hierarchy create a stress‑free monitoring environment.

Soft tones, clean grids, and clear alert hierarchy create a stress‑free monitoring environment.

Modular System Design

Modular System Design

A scalable UI library built for dashboards, mobile, and large‑screen factory displays.

A scalable UI library built for dashboards, mobile, and large‑screen factory displays.

Key Research Insights

Key Research Insights

Key Research Insights

Operators struggled with scattered machine information

Operators struggled with scattered machine information

I waste time switching screens just to confirm if the machine stopped due to overload or sensor error.

I waste time switching screens just to confirm if the machine stopped due to overload or sensor error.

Supervisors needed trends, not raw numbers

Supervisors needed trends, not raw numbers

Supervisors were overwhelmed with daily logs and CSV exports. What they actually needed was shift-level patterns, performance trends, and upcoming risks.

Supervisors were overwhelmed with daily logs and CSV exports. What they actually needed was shift-level patterns, performance trends, and upcoming risks.

Alert was a major problem

Alert was a major problem

Both operators and managers reported that machines sent too many non-critical alerts, causing them to ignore notifications over time.

Both operators and managers reported that machines sent too many non-critical alerts, causing them to ignore notifications over time.

Different roles needed different dashboards

Different roles needed different dashboards

An operator cares about today, while a supervisor cares about week/month performance. Mixing them created confusion.

An operator cares about today, while a supervisor cares about week/month performance. Mixing them created confusion.

On-floor navigation required mobile-first thinking

On-floor navigation required mobile-first thinking

Operators often accessed the system while walking, wearing gloves, or under noise, meaning traditional dashboards didn’t work.

Operators often accessed the system while walking, wearing gloves, or under noise, meaning traditional dashboards didn’t work.

Data consistency issues caused trust problems

Data consistency issues caused trust problems

Users complained that they didn't trust certain values due to inconsistent sensor readings or delays.

Users complained that they didn't trust certain values due to inconsistent sensor readings or delays.

Process

Process

Process

Research & Strategy

1 WEEK

Research

User Persona

Empathy map

Information Architecture

Design & Branding

2 WEEK

Strategy

Wireframing

UI Design

Visual Design

Delivery Execution

3 WEEK

Development

Testing

Finalization

Prototype

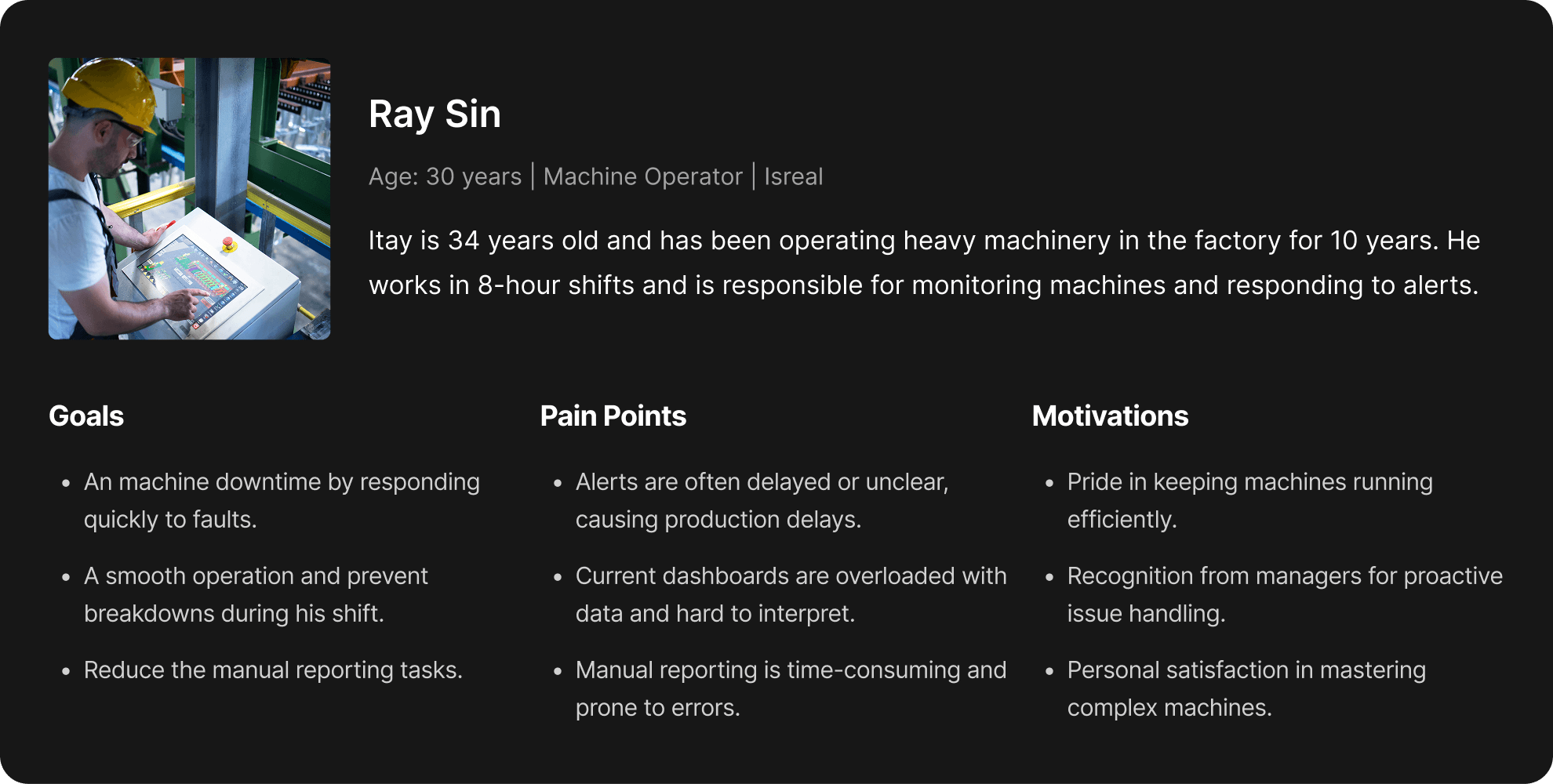

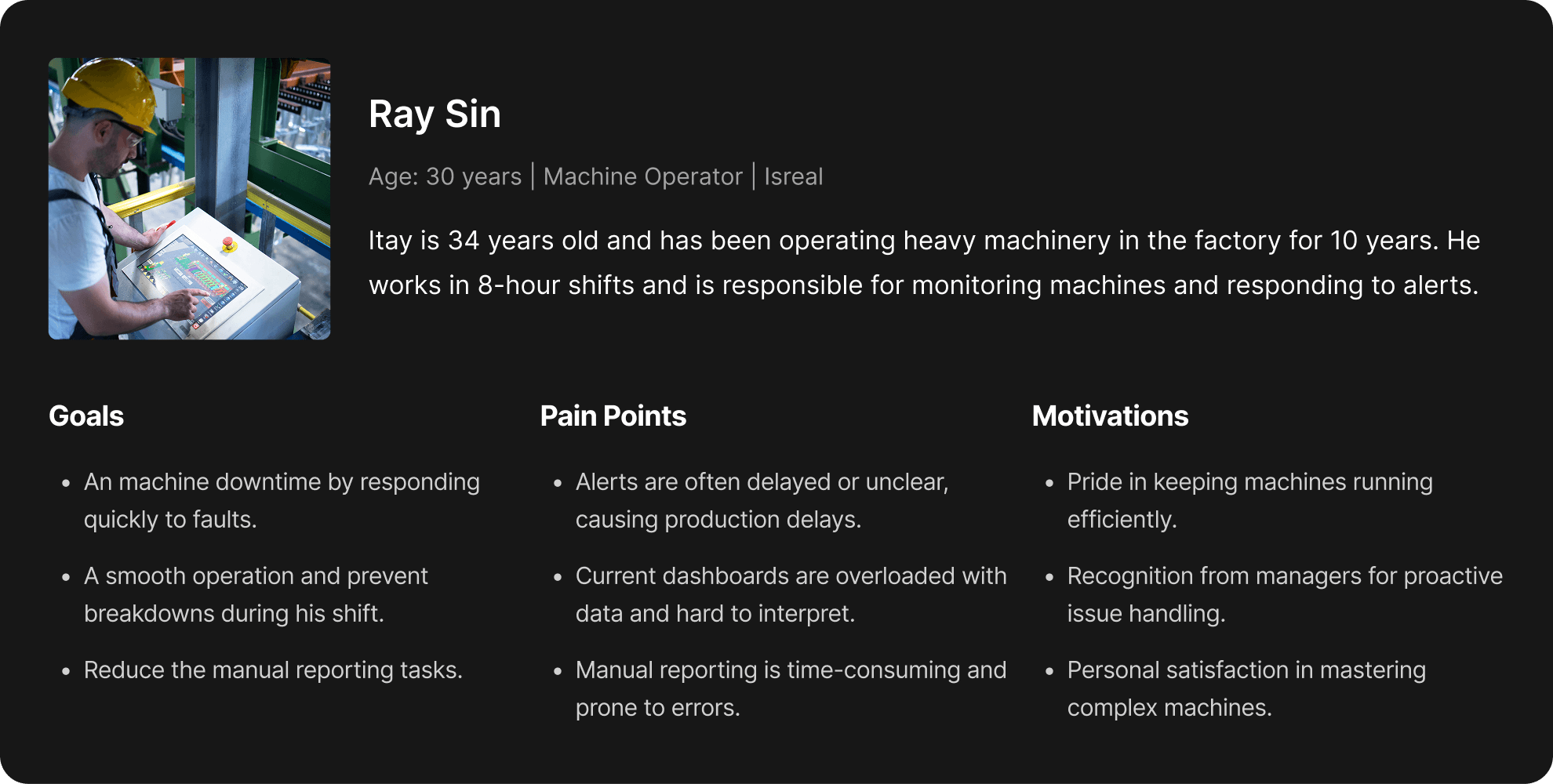

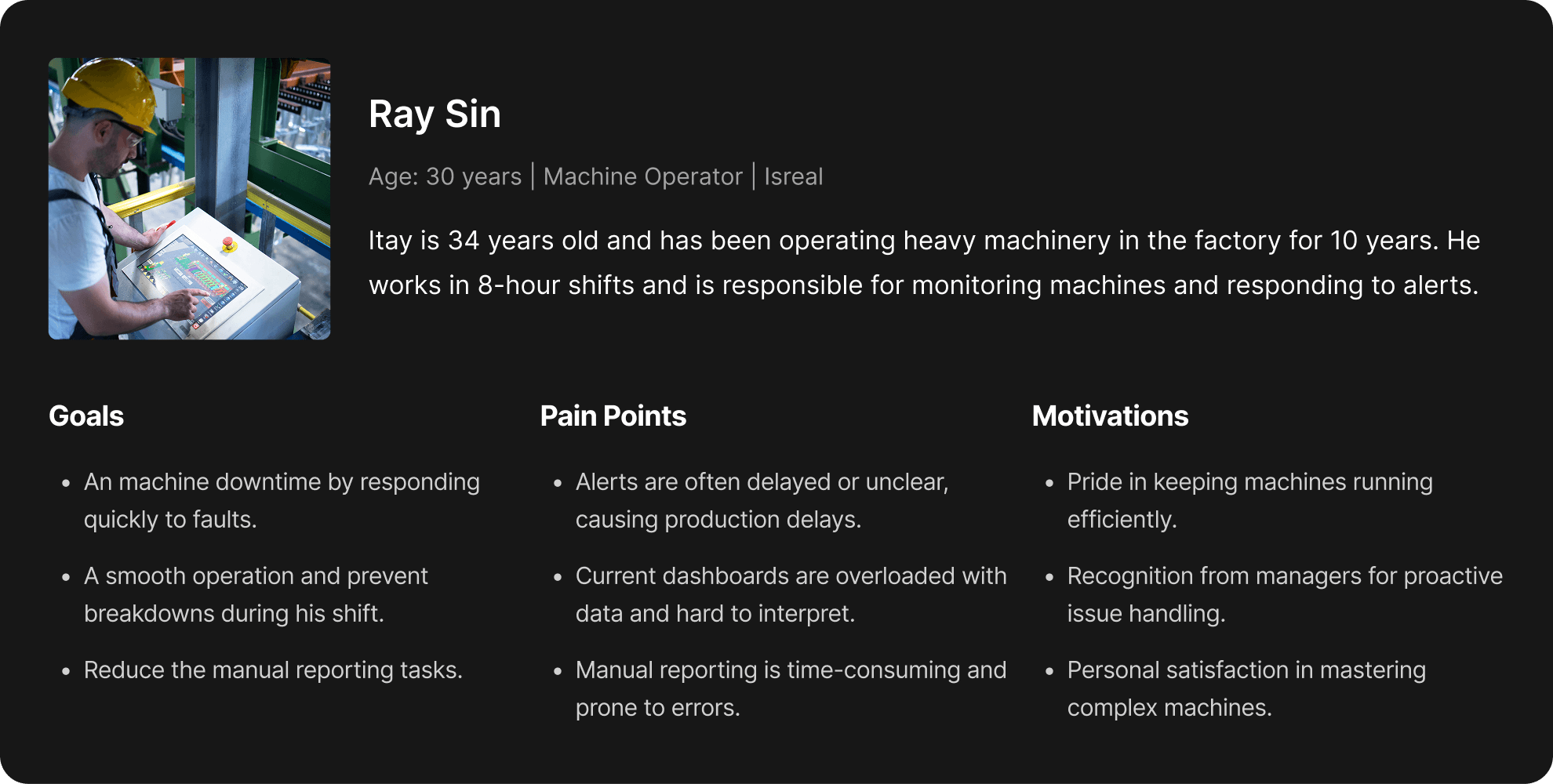

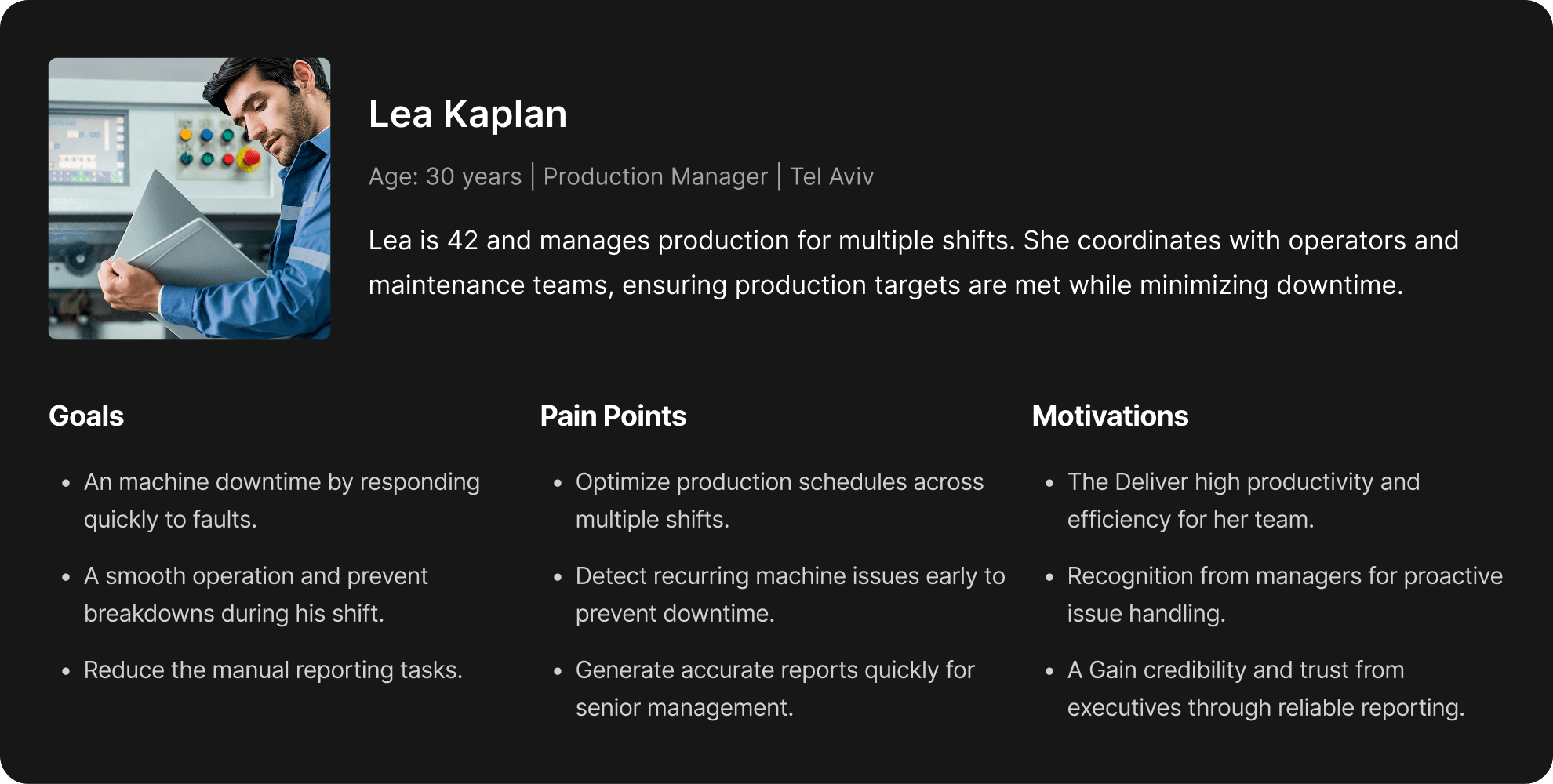

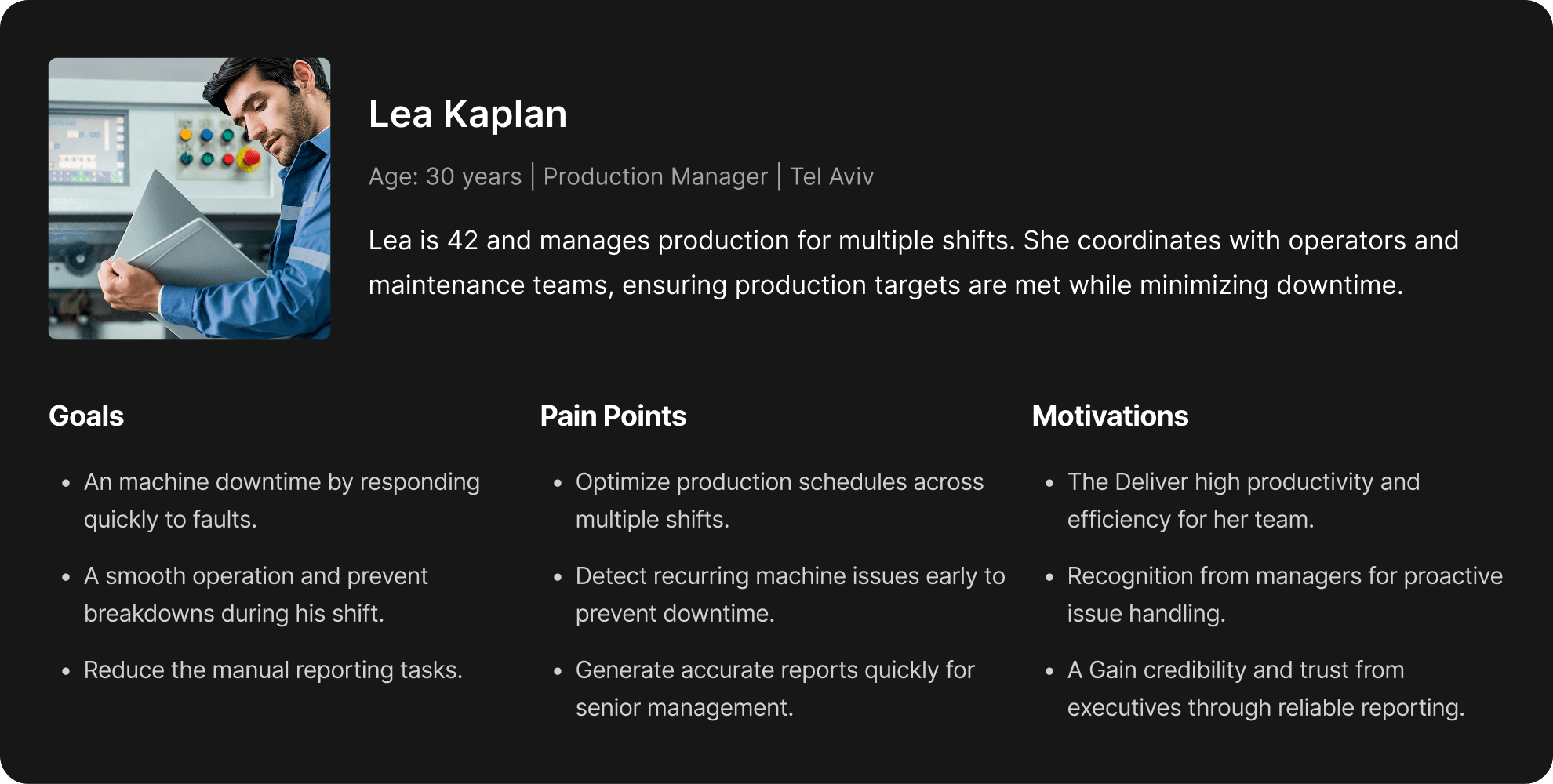

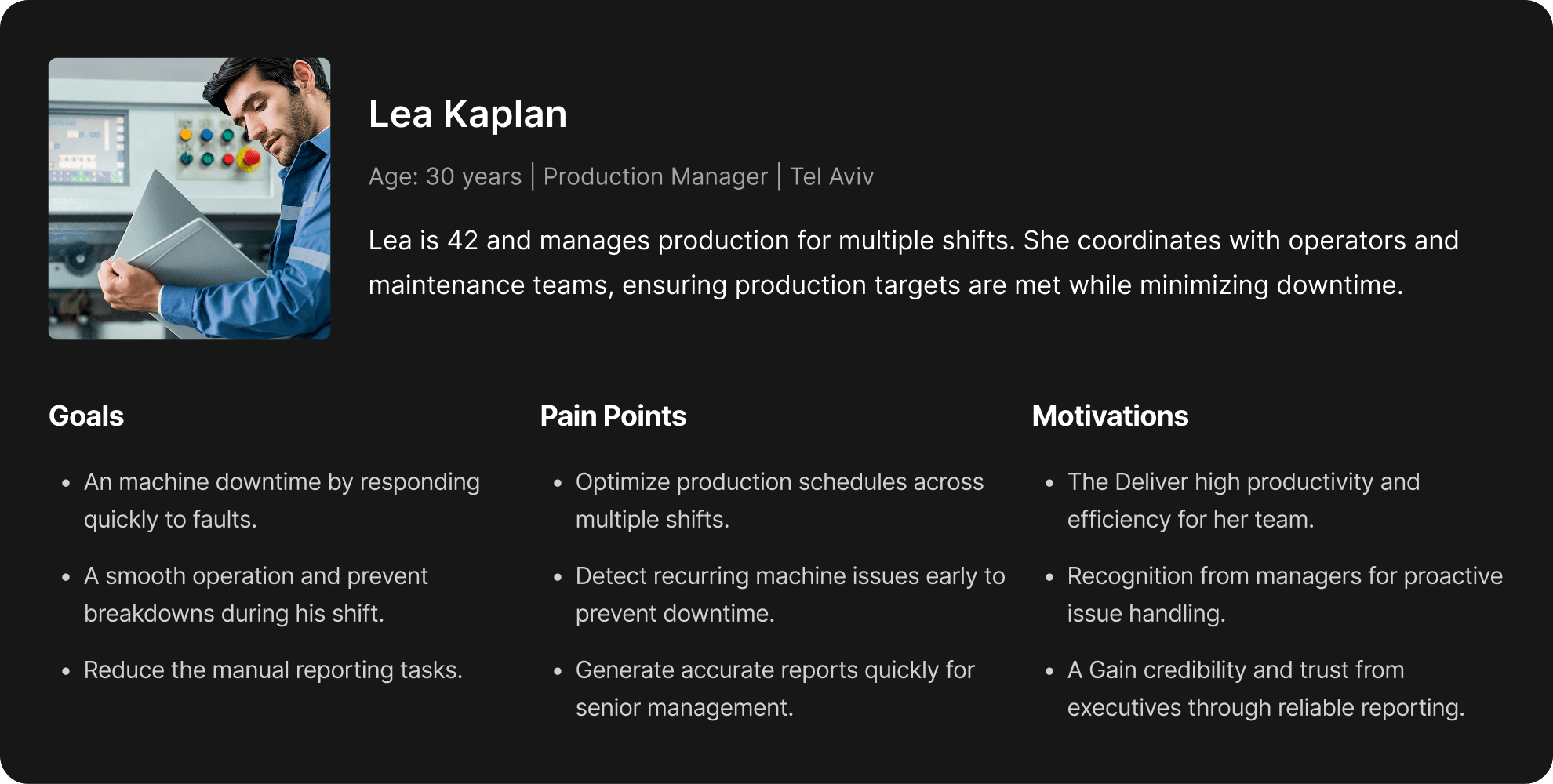

User Persona

User Persona

User Persona

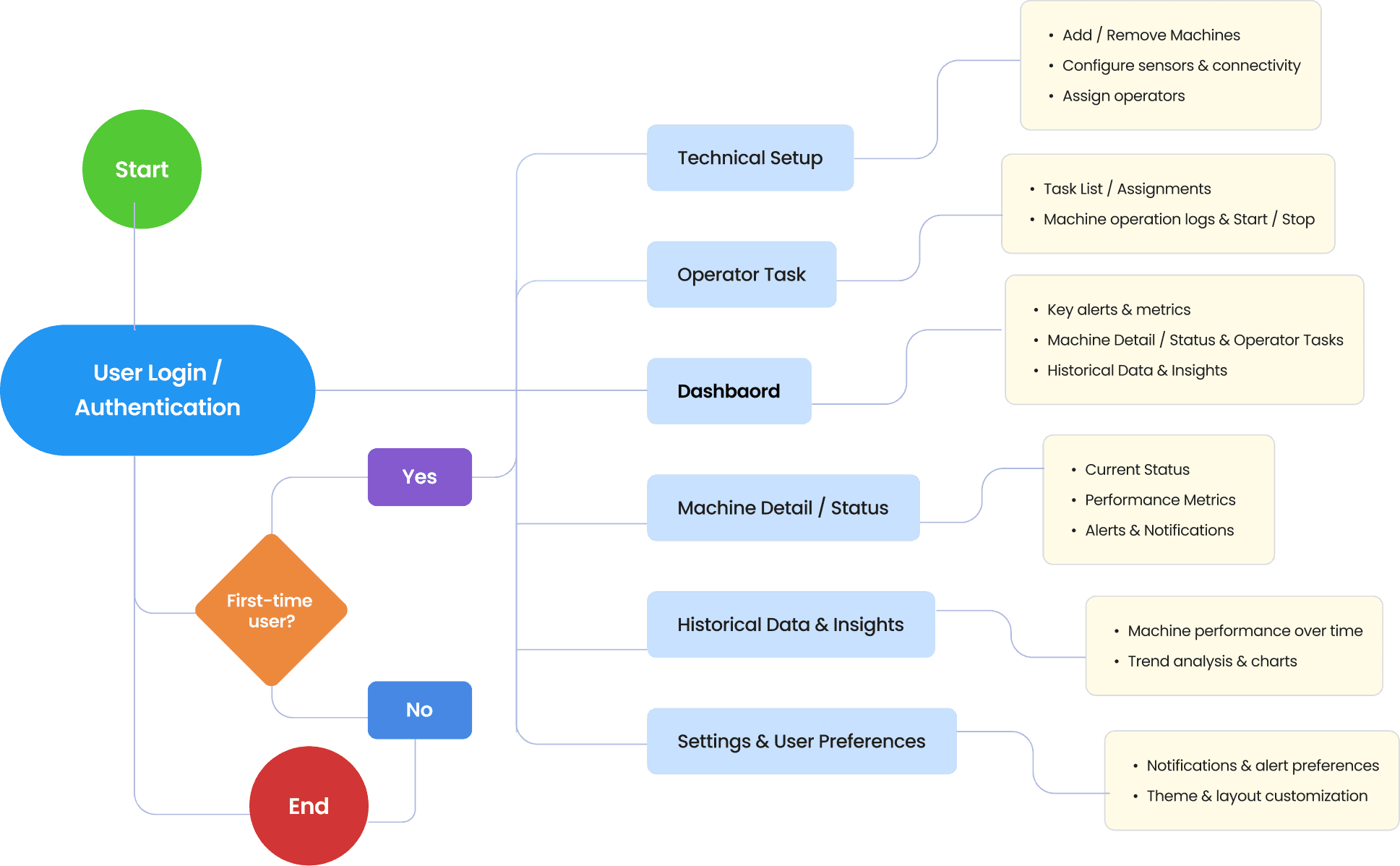

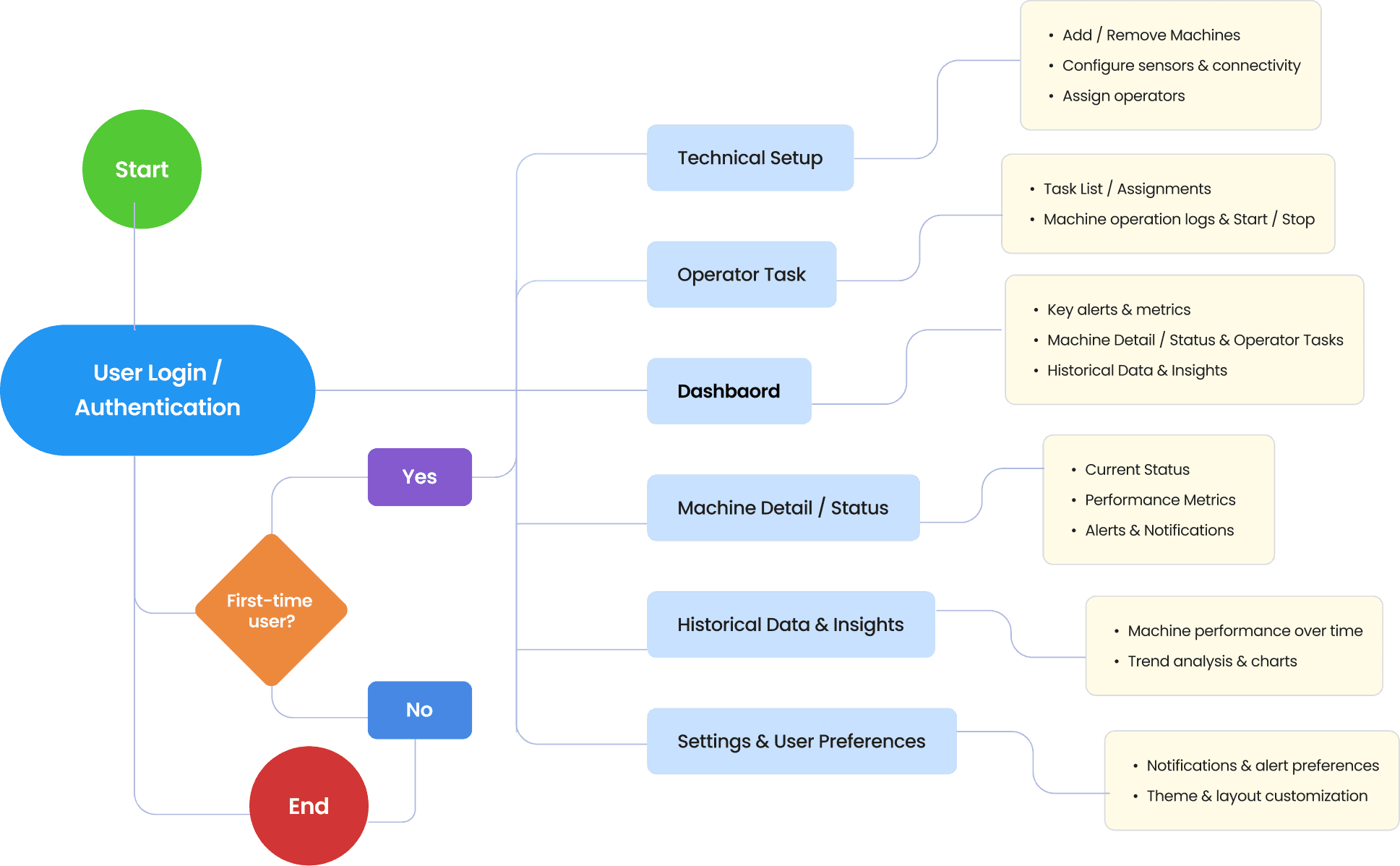

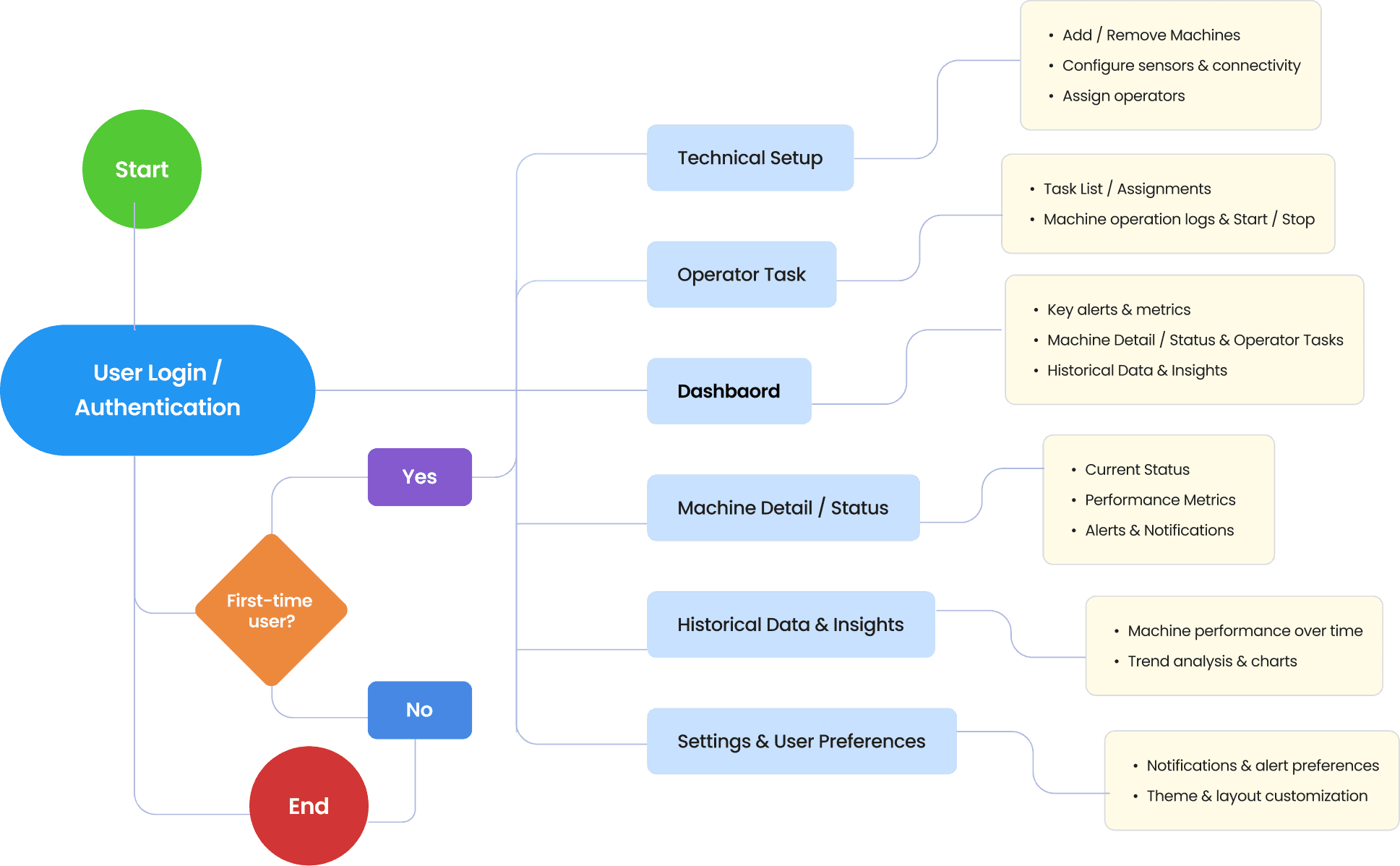

Product Architecture

Product Architecture

Product Architecture

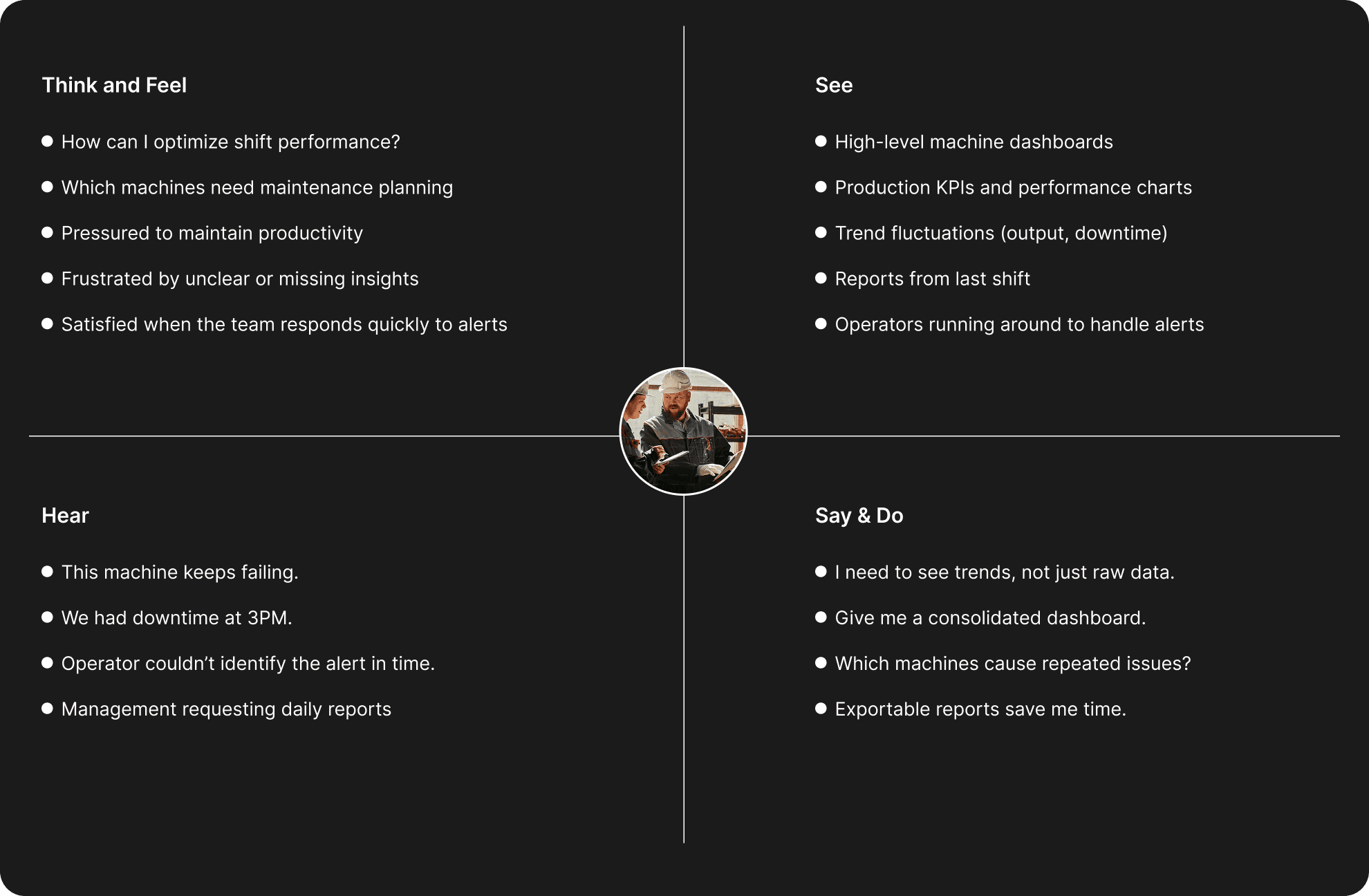

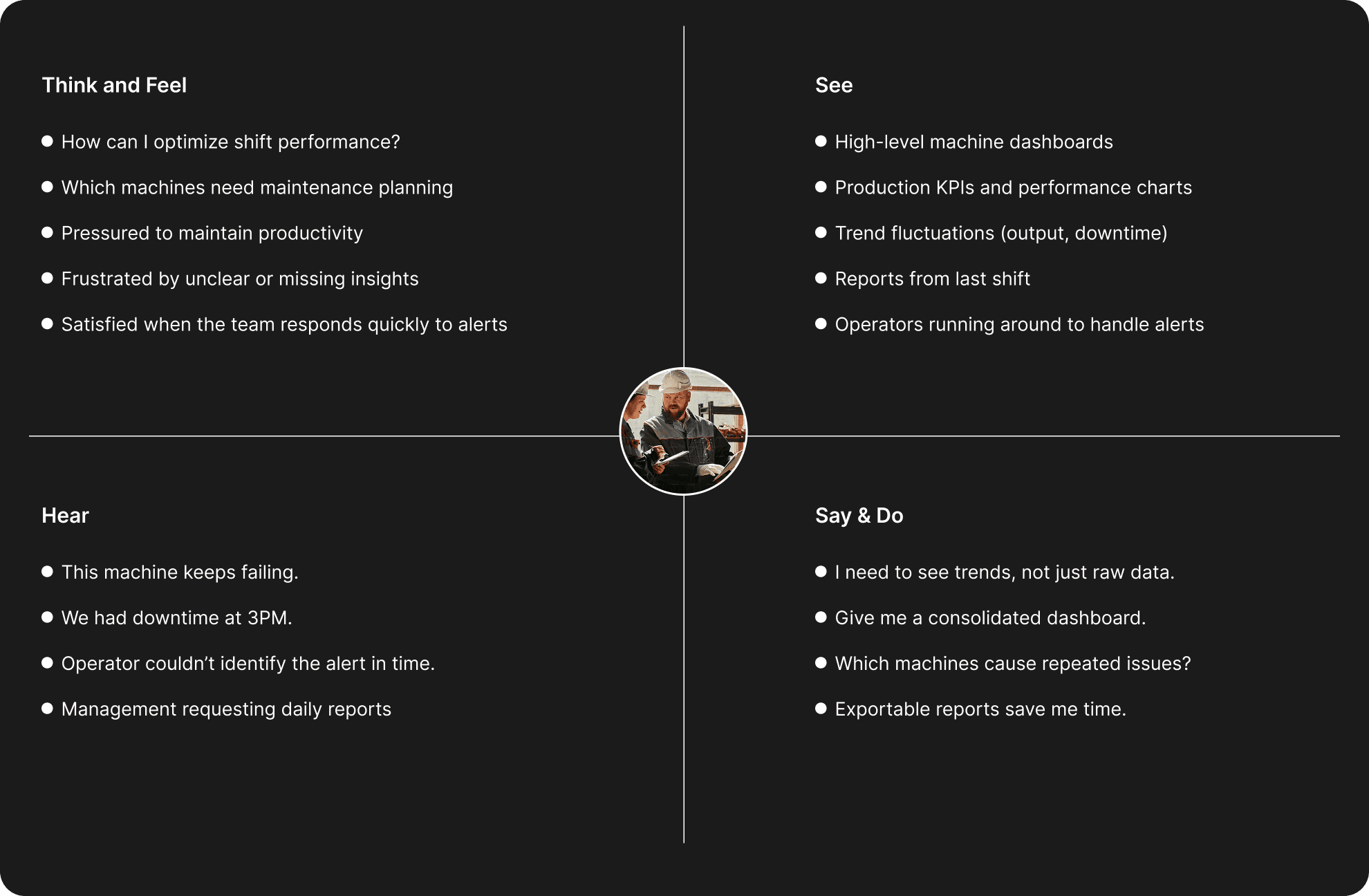

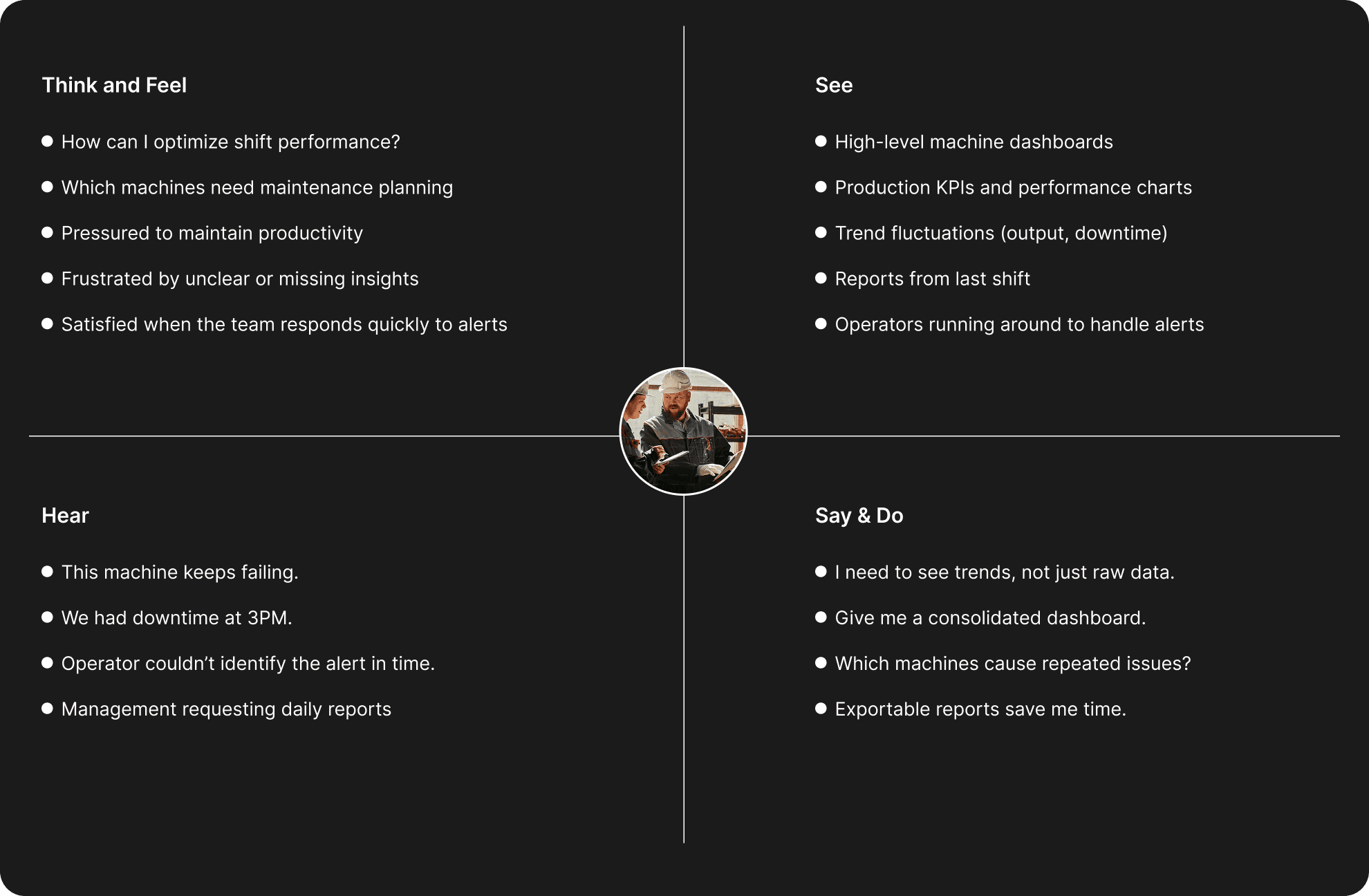

Empathy Mapping

Empathy Mapping

Empathy Mapping

Pain Points (Operator)

Pain Points (Operator)

Pain Points (Operator)

Hard to track multiple machines while working on tasks

Must switch screens to find basic machine info

Alerts look similar and are easy to miss

Hard to monitor machines while moving around the factory

No clear priority on which machine needs urgent attention

Hard to track multiple machines while working on tasks

Must switch screens to find basic machine info

Alerts look similar and are easy to miss

Hard to monitor machines while moving around the factory

No clear priority on which machine needs urgent attention

Opportunities (Operator)

Opportunities (Operator)

Opportunities (Operator)

One single dashboard showing all machine status

Highly visible, color-coded critical alerts

Automatic logging reduces workload

Minimalistic, easy-to-scan interface

Mobile-friendly access during movement

One single dashboard showing all machine status

Highly visible, color-coded critical alerts

Automatic logging reduces workload

Minimalistic, easy-to-scan interface

Mobile-friendly access during movement

Pain Points (Supervisor/Manager)

Pain Points (Supervisor/Manager)

Pain Points (Supervisor/Manager)

They receive raw numbers, not insights

Hard to identify recurring machine failures

Reporting requires manual effort

Cannot compare machine performance across shifts

Lack of custom dashboards tailored to managerial needs

They receive raw numbers, not insights

Hard to identify recurring machine failures

Reporting requires manual effort

Cannot compare machine performance across shifts

Lack of custom dashboards tailored to managerial needs

Pain poits (Operator)

Pain poits (Operator)

Pain poits (Operator)

Trend-based dashboards (downtime, output, temperature)

Predictive maintenance alerts

Automated report generation (PDF/CSV)

Machine health score for planning and budgeting

Insights for maintenance and workforce scheduling

Trend-based dashboards (downtime, output, temperature)

Predictive maintenance alerts

Automated report generation (PDF/CSV)

Machine health score for planning and budgeting

Insights for maintenance and workforce scheduling

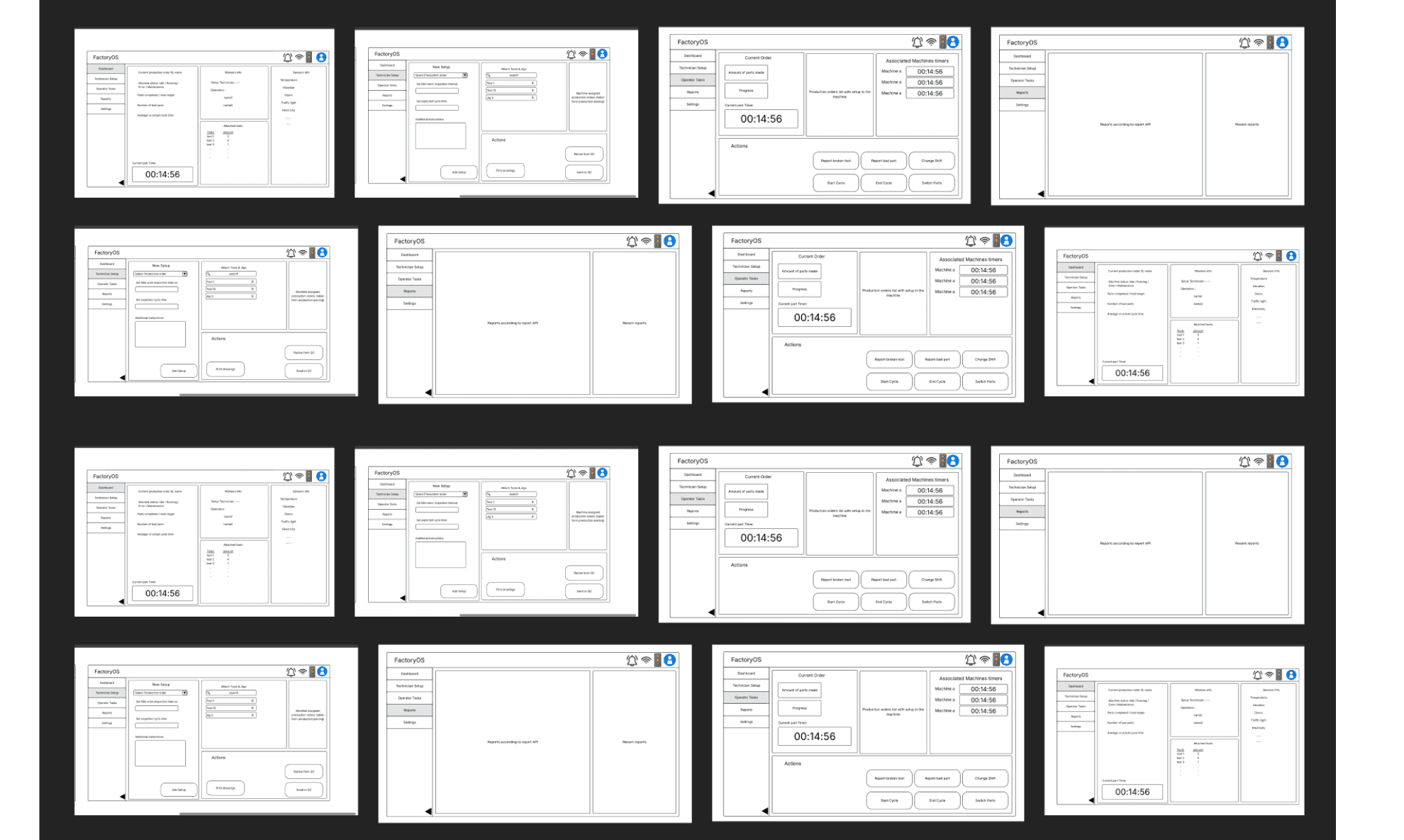

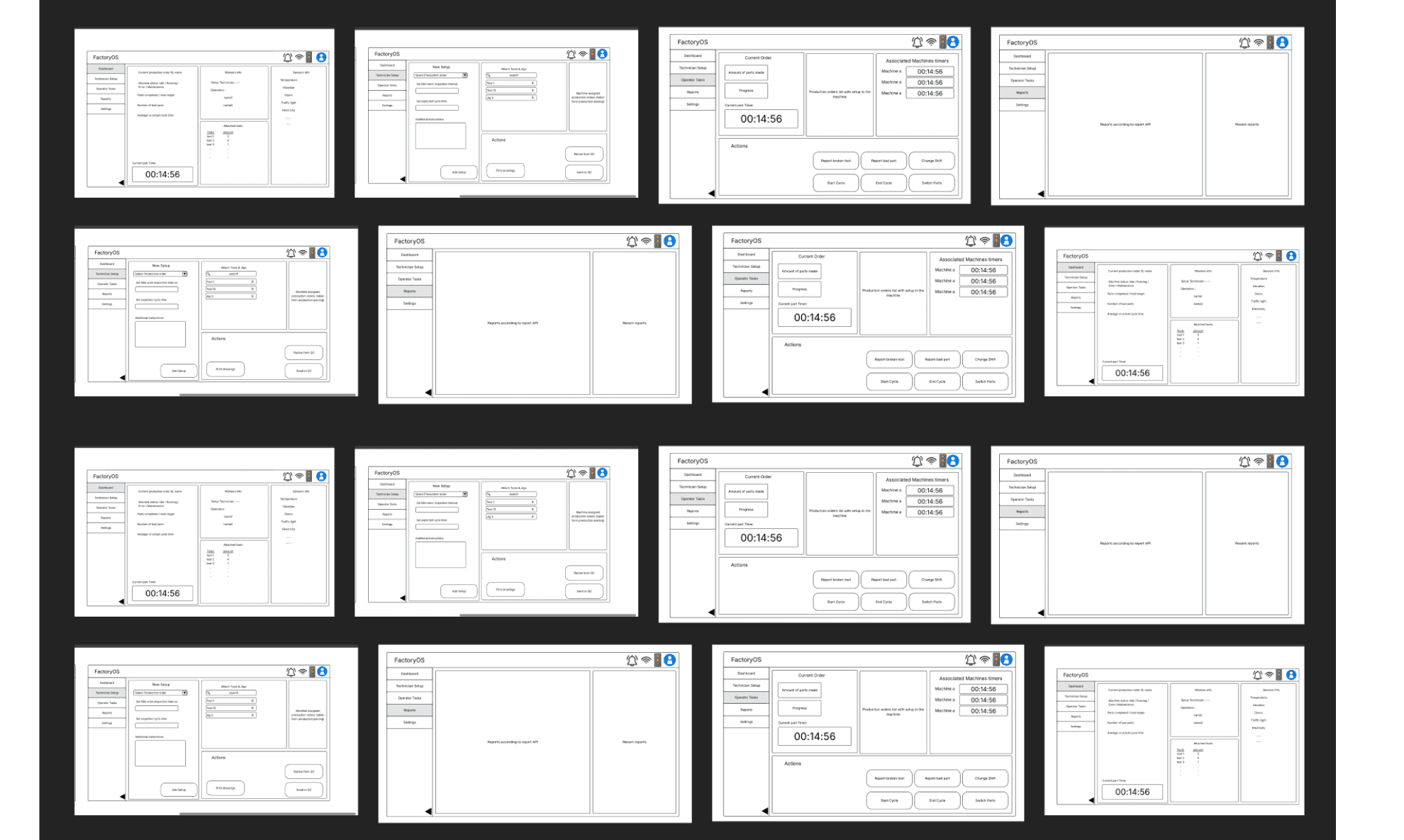

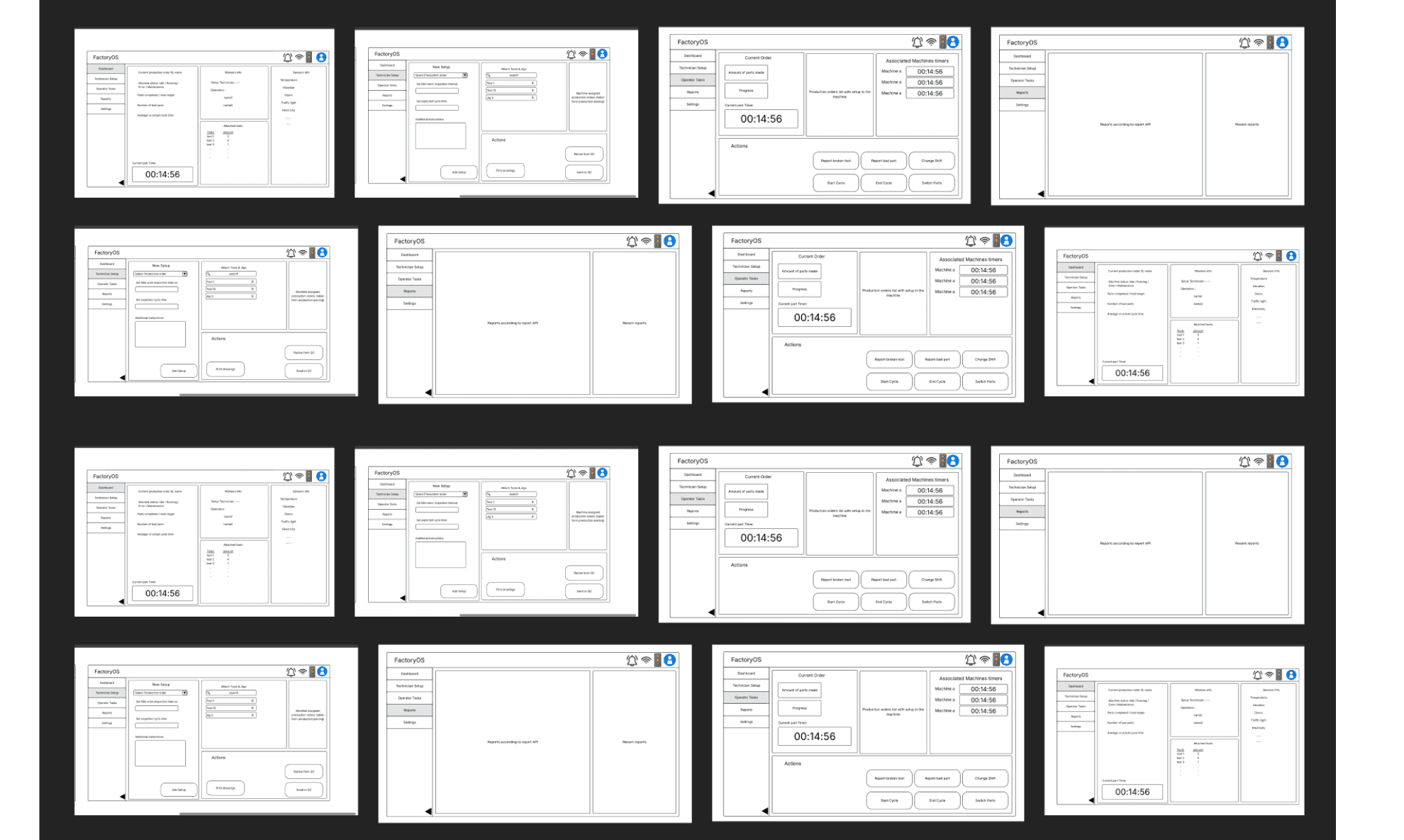

Wireframe

Wireframe

Wireframe

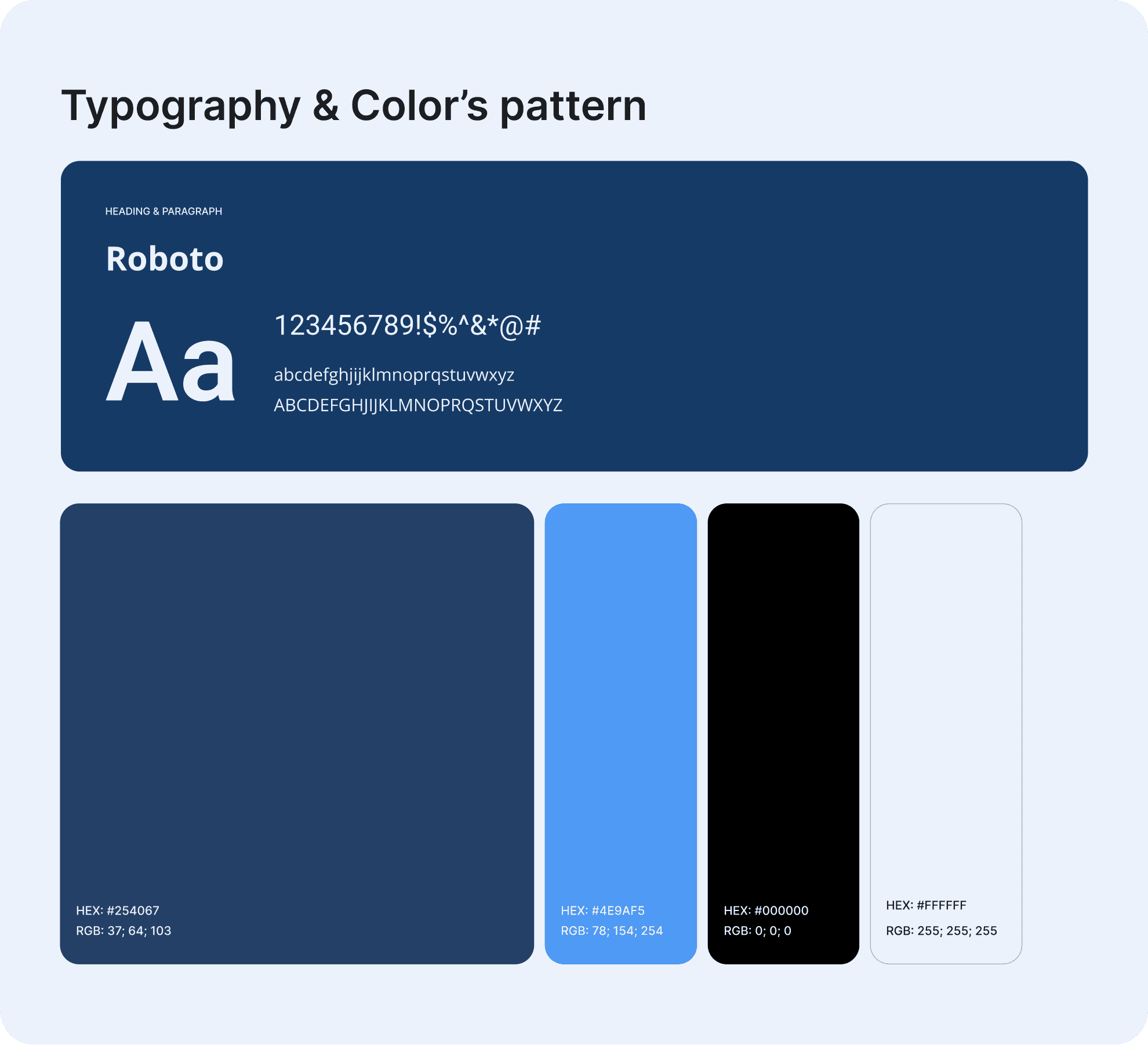

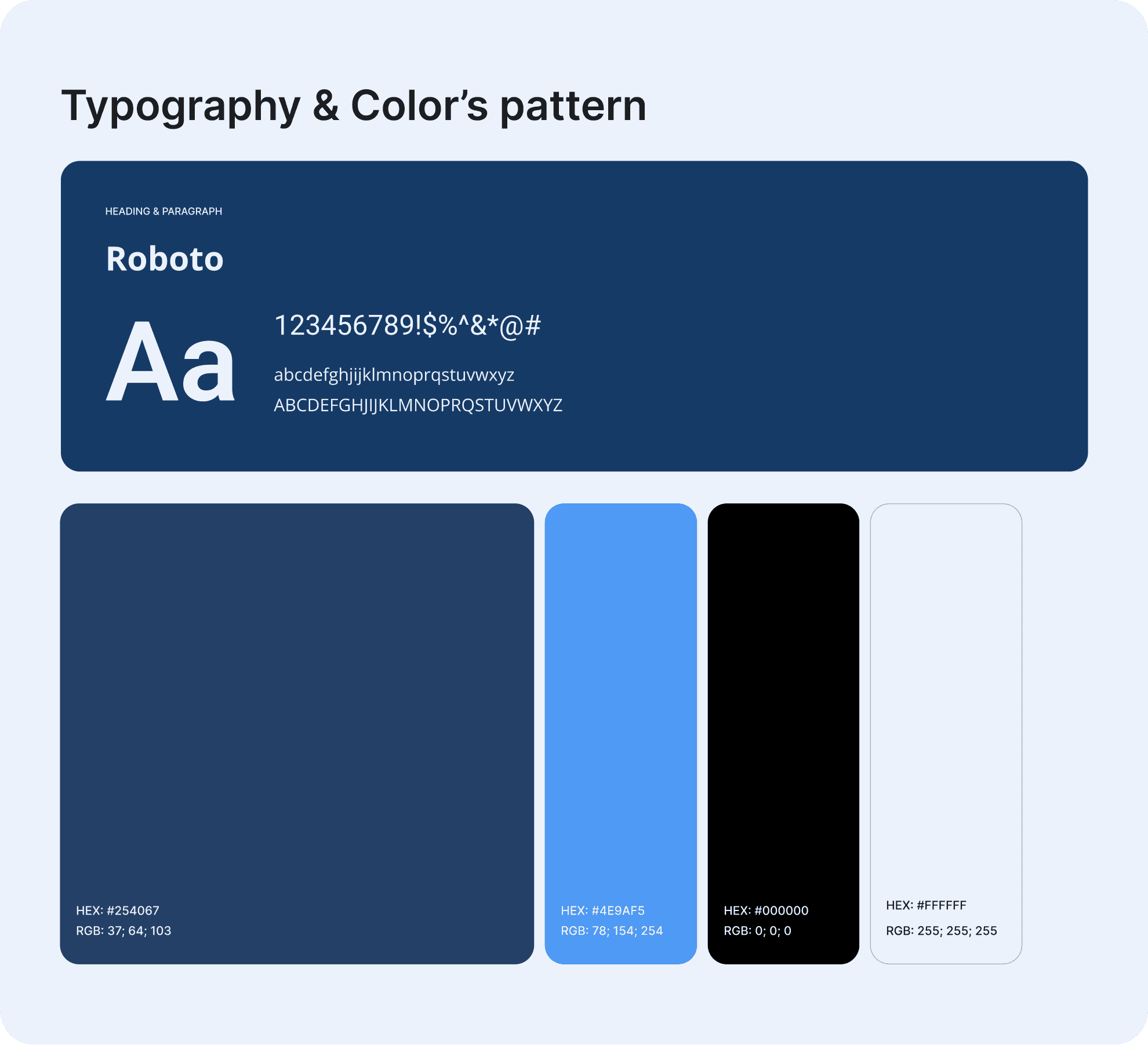

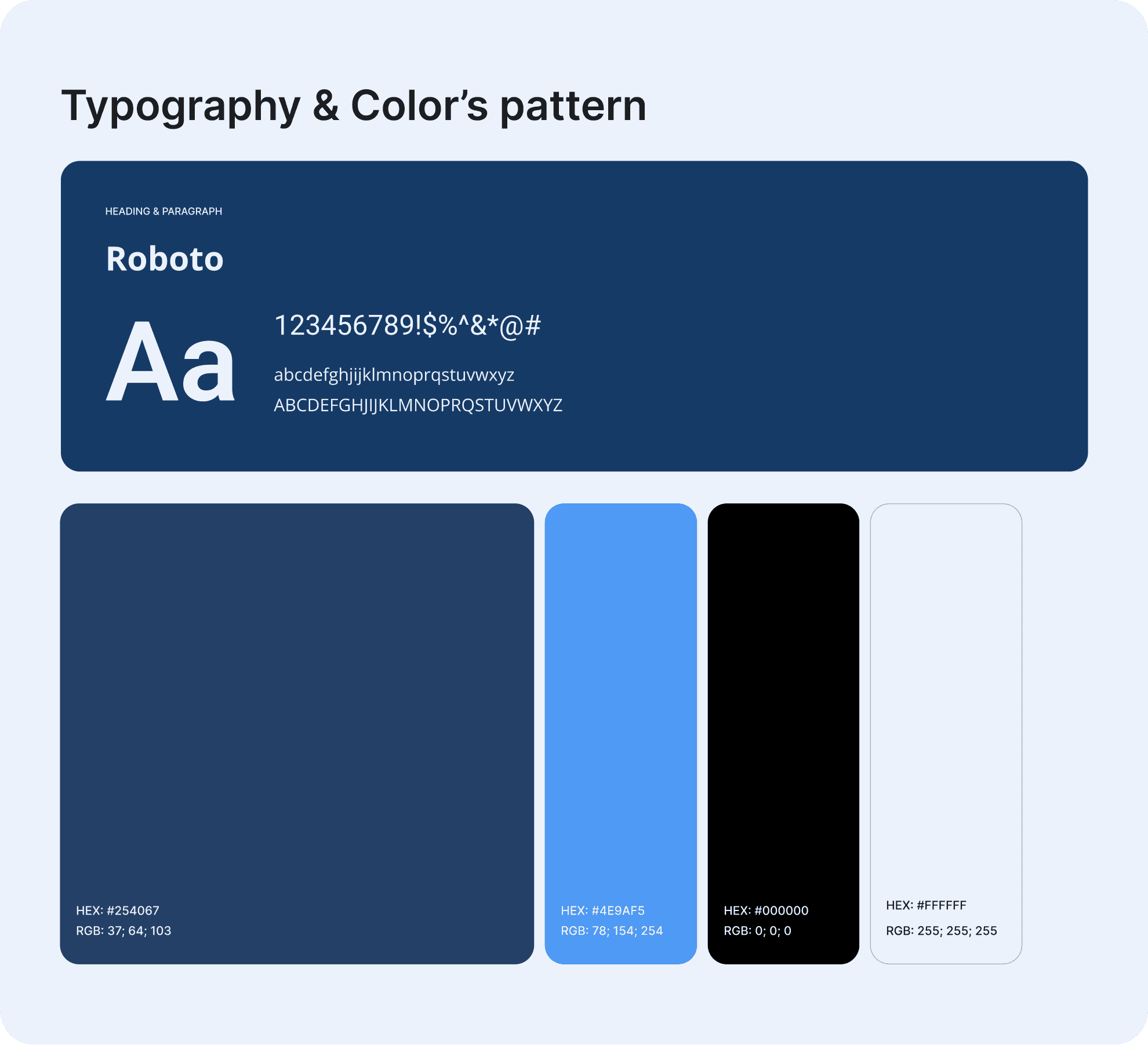

Style Guide

Style Guide

Style Guide

A balanced mix of bold Colours, typography, subtle neutrals, and intuitive iconography ensures data is readable, actionable, and easy to scan in high-pressure factory environments.

A balanced mix of bold Colours, typography, subtle neutrals, and intuitive iconography ensures data is readable, actionable, and easy to scan in high-pressure factory environments.

A balanced mix of bold Colours, typography, subtle neutrals, and intuitive iconography ensures data is readable, actionable, and easy to scan in high-pressure factory environments.

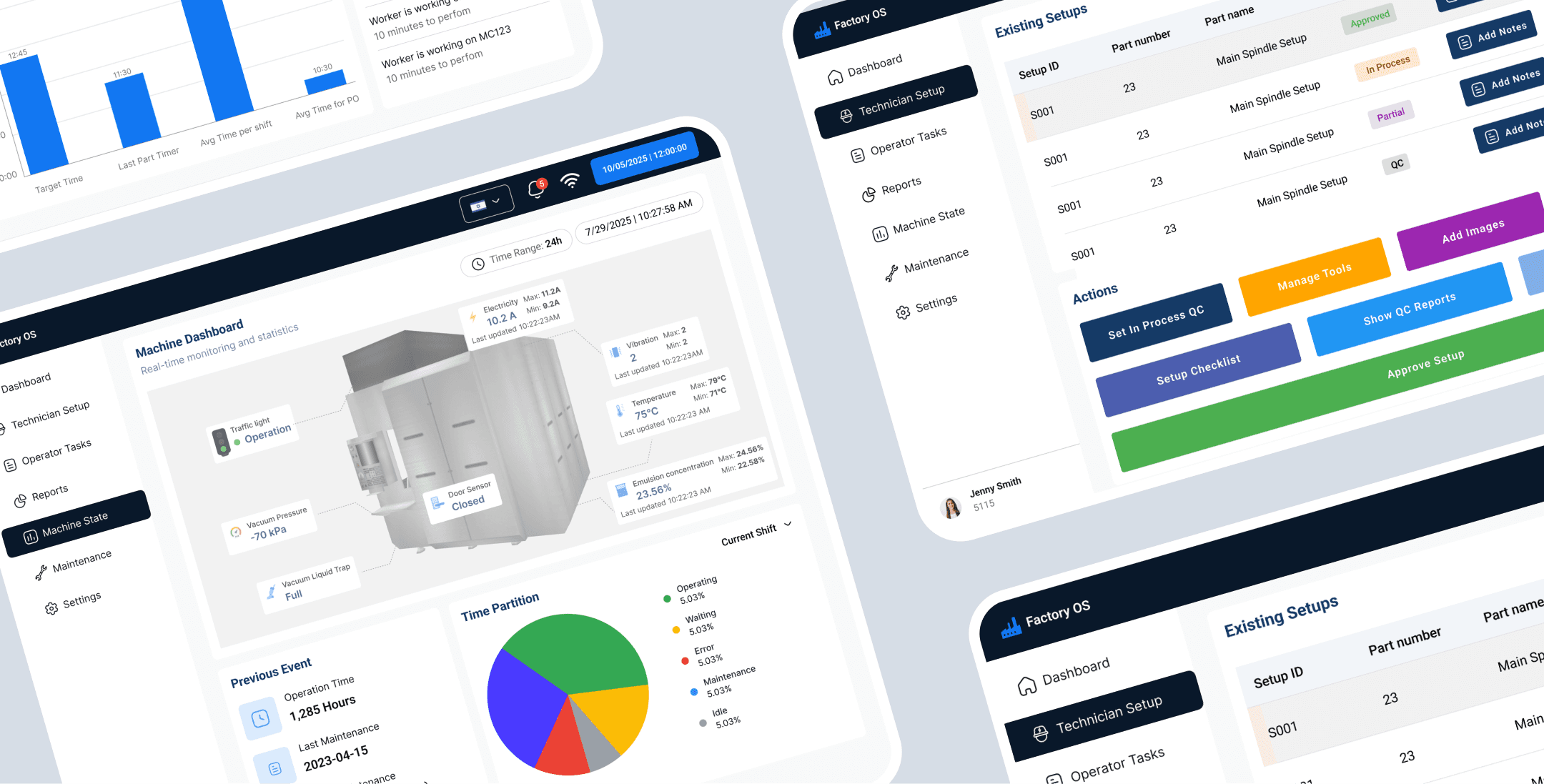

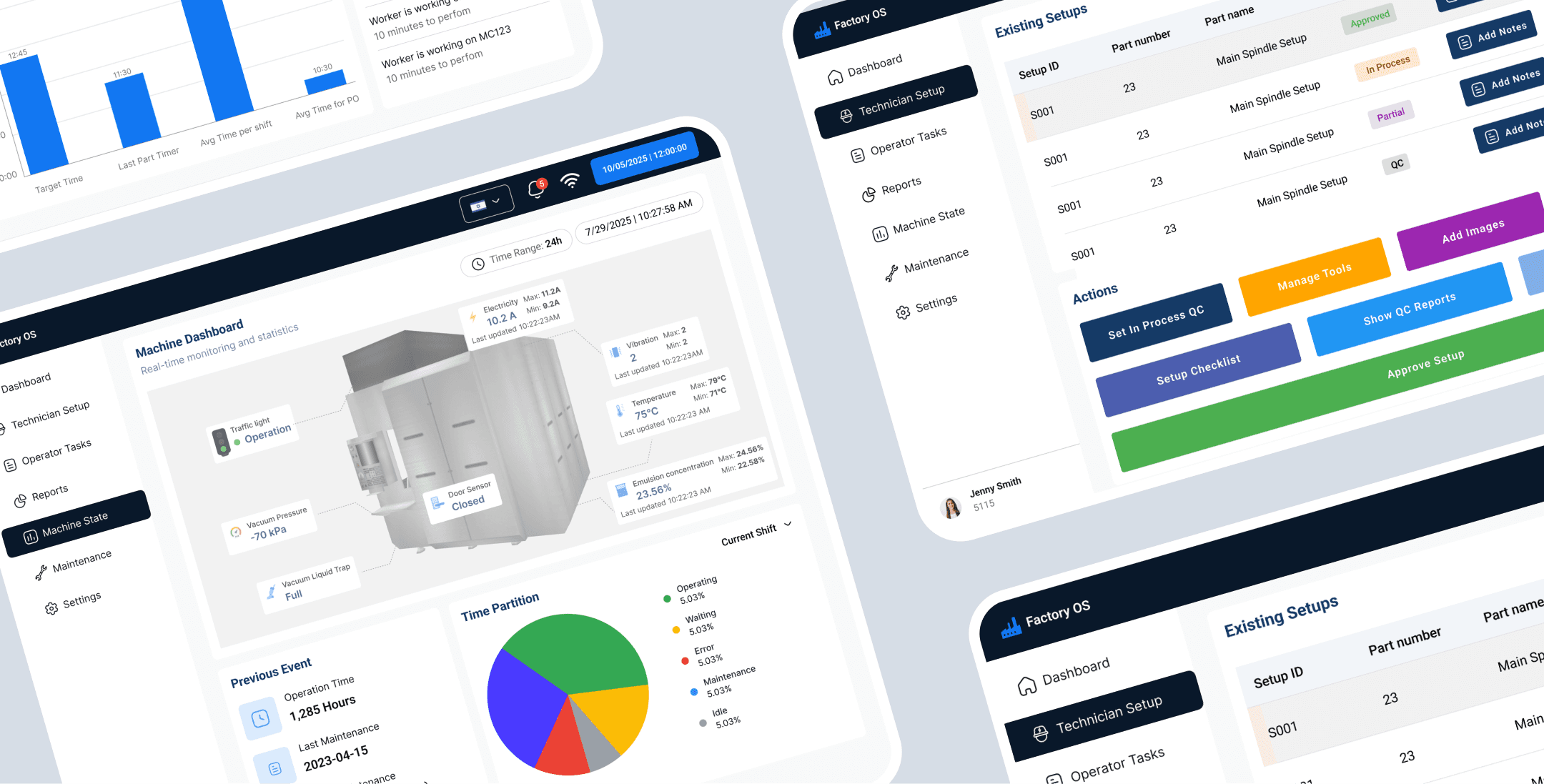

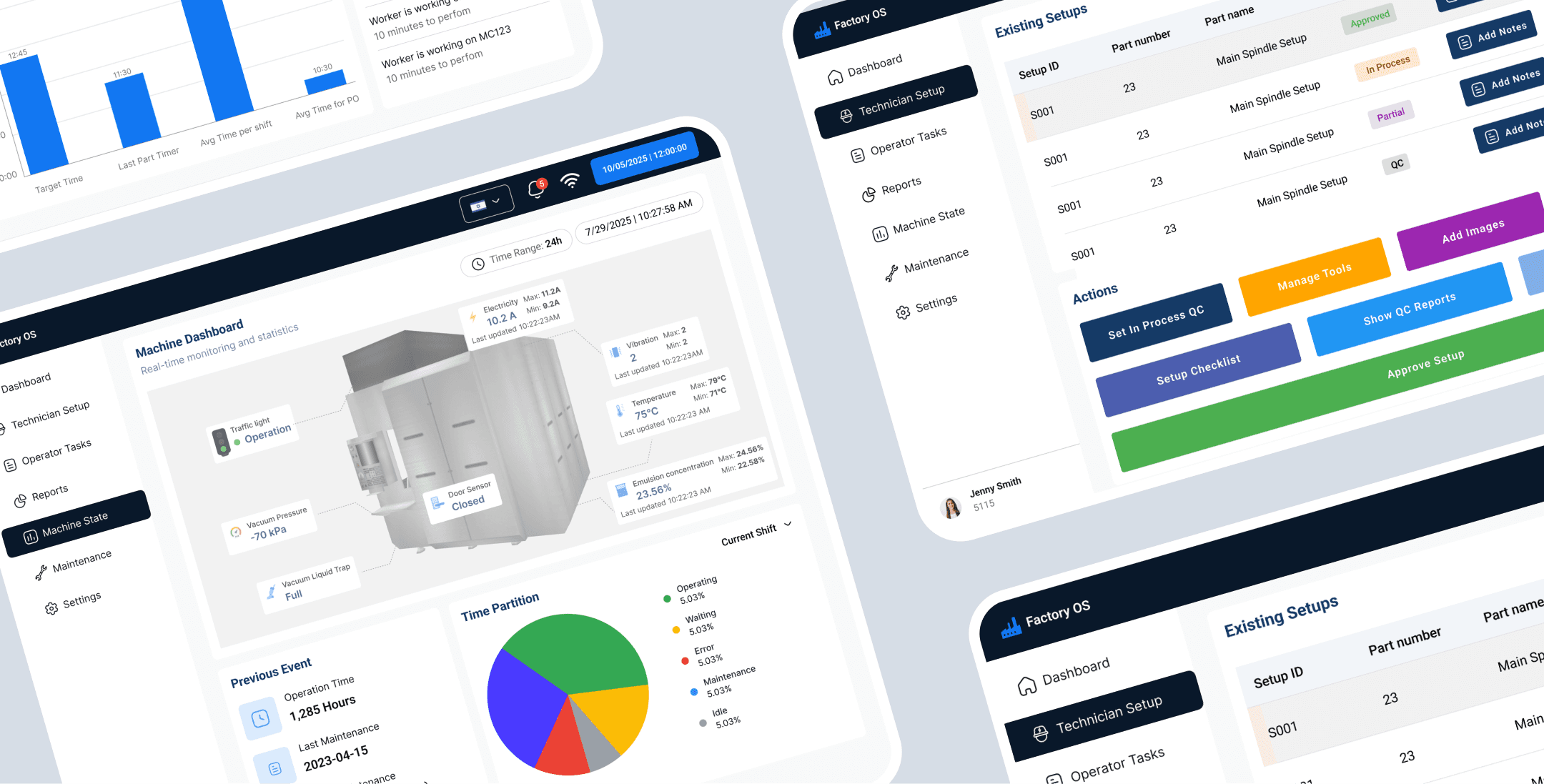

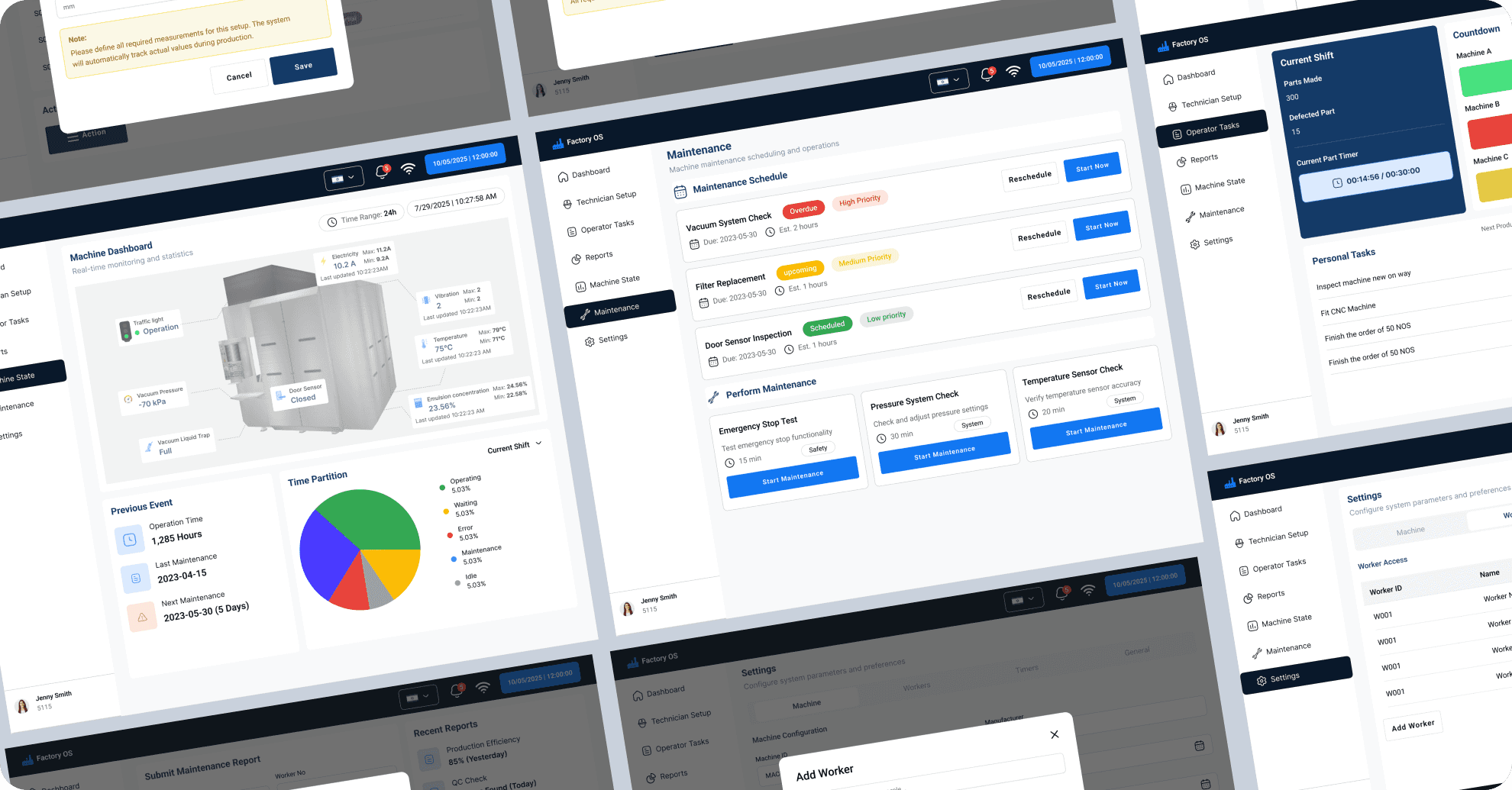

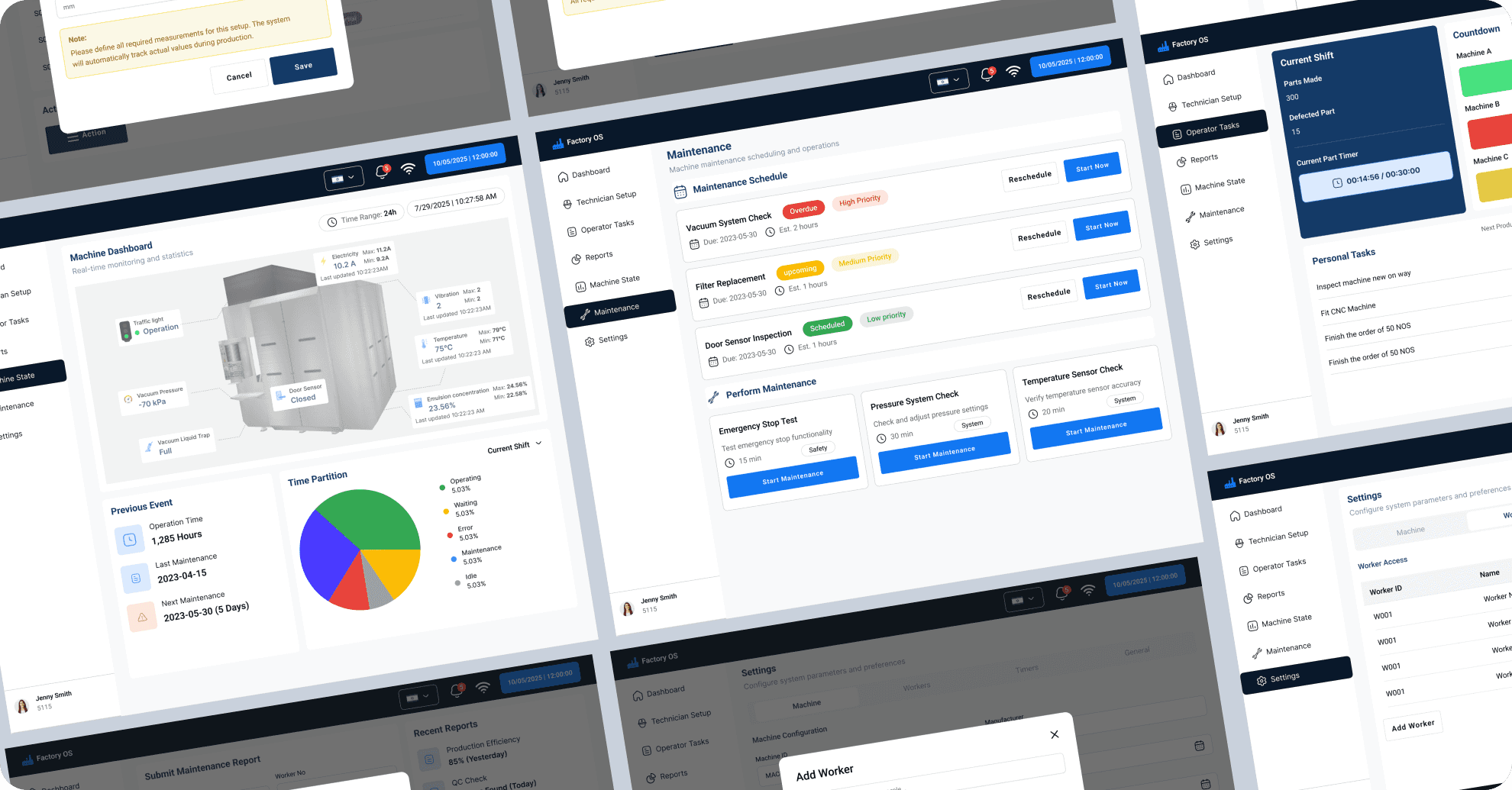

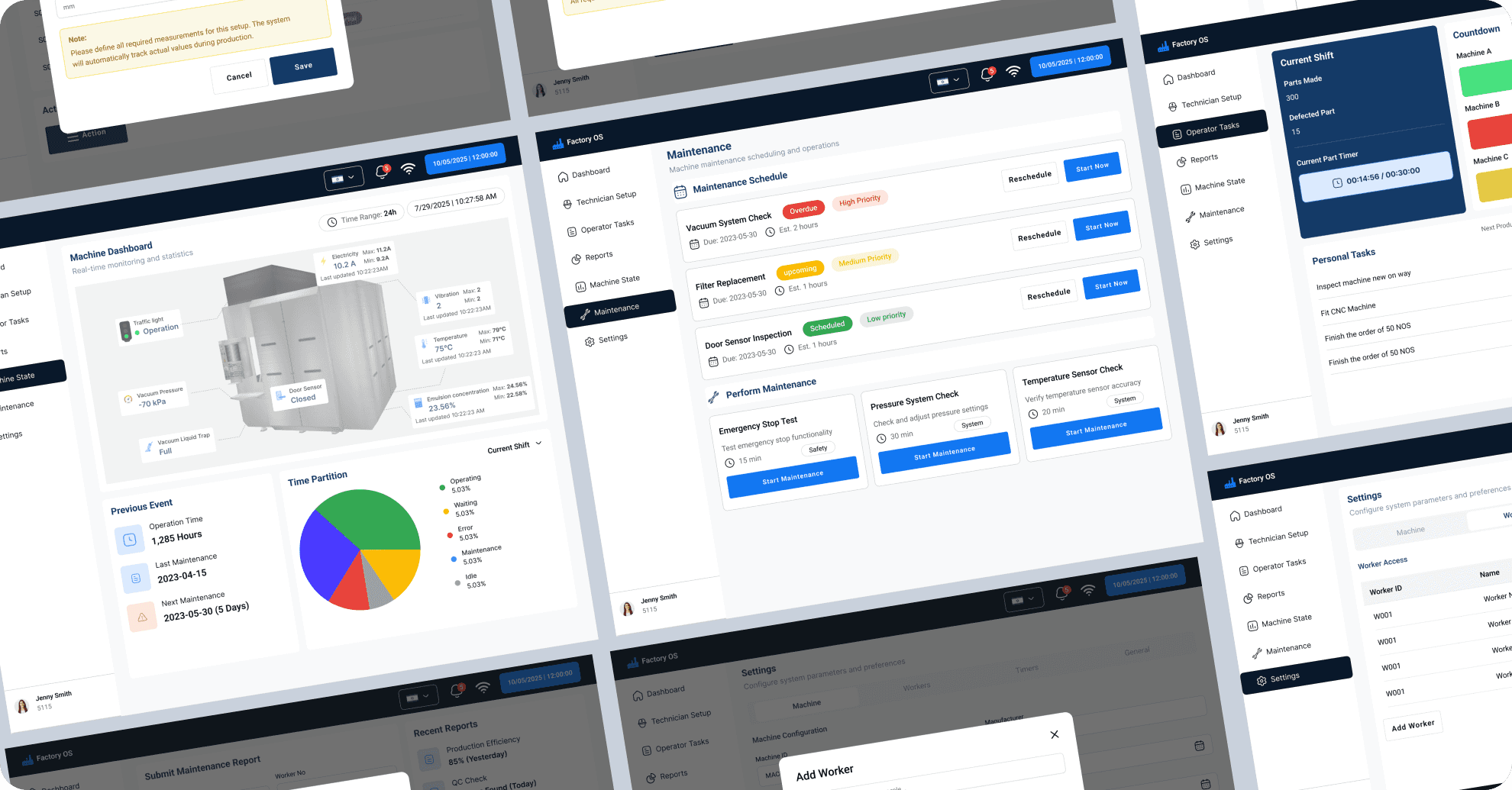

Final designs

Final designs

Final designs

The final product delivers a seamless IoT monitoring experience that enables teams to act faster, prevent failures, and maintain continuous production. With clearer insights, reduced downtime, and higher technician efficiency, factories achieved stronger performance and a more predictable, data-driven operation.

The final product delivers a seamless IoT monitoring experience that enables teams to act faster, prevent failures, and maintain continuous production. With clearer insights, reduced downtime, and higher technician efficiency, factories achieved stronger performance and a more predictable, data-driven operation.

The final product delivers a seamless IoT monitoring experience that enables teams to act faster, prevent failures, and maintain continuous production. With clearer insights, reduced downtime, and higher technician efficiency, factories achieved stronger performance and a more predictable, data-driven operation.

Dashboard / Home Screen

Dashboard / Home Screen

The dashboard gives a quick, high-level overview of all machines with color-coded health cards and live summary metrics. Users can instantly spot issues through clear green/amber/red indicators and mini performance trends.

The dashboard gives a quick, high-level overview of all machines with color-coded health cards and live summary metrics. Users can instantly spot issues through clear green/amber/red indicators and mini performance trends.

The dashboard gives a quick, high-level overview of all machines with color-coded health cards and live summary metrics. Users can instantly spot issues through clear green/amber/red indicators and mini performance trends.

A Quick actions like “View Alerts” or “Add Device” make the dashboard both informative and actionable, helping teams respond faster.

A Quick actions like “View Alerts” or “Add Device” make the dashboard both informative and actionable, helping teams respond faster.

A Quick actions like “View Alerts” or “Add Device” make the dashboard both informative and actionable, helping teams respond faster.

Machine Detail

Machine Detail

This screen shows real-time machine metrics, historical trends, and predictive behavior in one place. Users can view alerts, maintenance history, and data patterns to understand the root cause of issues.

This screen shows real-time machine metrics, historical trends, and predictive behavior in one place. Users can view alerts, maintenance history, and data patterns to understand the root cause of issues.

This screen shows real-time machine metrics, historical trends, and predictive behavior in one place. Users can view alerts, maintenance history, and data patterns to understand the root cause of issues.

With quick actions like assigning technicians or scheduling maintenance, teams can act immediately without switching screens.

With quick actions like assigning technicians or scheduling maintenance, teams can act immediately without switching screens.

With quick actions like assigning technicians or scheduling maintenance, teams can act immediately without switching screens.

Operator Task

Operator Task

The operator task screen shows a clear list of assigned tasks such as inspections, machine checks, or routine maintenance steps. Each task includes priority, due time, and the machine it belongs to, helping operators stay organized. Simple actions like “Start,” “Mark Complete,” or “Add Notes” keep workflows smooth and trackable. This screen ensures operators always know what to do next and reduces delays on the factory floor.

The operator task screen shows a clear list of assigned tasks such as inspections, machine checks, or routine maintenance steps. Each task includes priority, due time, and the machine it belongs to, helping operators stay organized. Simple actions like “Start,” “Mark Complete,” or “Add Notes” keep workflows smooth and trackable. This screen ensures operators always know what to do next and reduces delays on the factory floor.

The operator task screen shows a clear list of assigned tasks such as inspections, machine checks, or routine maintenance steps. Each task includes priority, due time, and the machine it belongs to, helping operators stay organized. Simple actions like “Start,” “Mark Complete,” or “Add Notes” keep workflows smooth and trackable. This screen ensures operators always know what to do next and reduces delays on the factory floor.

Technician / Device Setup

Technician / Device Setup

The setup flow makes onboarding devices easy with QR pairing, manual entry, and live connection status. Users can assign machines, configure roles, and manage permissions for technicians, operators, and managers. This guided process reduces errors and keeps the IoT environment secure and organized.

The setup flow makes onboarding devices easy with QR pairing, manual entry, and live connection status. Users can assign machines, configure roles, and manage permissions for technicians, operators, and managers. This guided process reduces errors and keeps the IoT environment secure and organized.

The setup flow makes onboarding devices easy with QR pairing, manual entry, and live connection status. Users can assign machines, configure roles, and manage permissions for technicians, operators, and managers. This guided process reduces errors and keeps the IoT environment secure and organized.

Reports / Analytics

Reports / Analytics

Reports visualize key metrics like performance trends, downtime, and alert frequency across custom time ranges. Predictive risk indicators help managers plan maintenance before failures occur. Users can export insights as PDF/CSV to share with teams and support data-driven decisions.

Reports visualize key metrics like performance trends, downtime, and alert frequency across custom time ranges. Predictive risk indicators help managers plan maintenance before failures occur. Users can export insights as PDF/CSV to share with teams and support data-driven decisions.

Reports visualize key metrics like performance trends, downtime, and alert frequency across custom time ranges. Predictive risk indicators help managers plan maintenance before failures occur. Users can export insights as PDF/CSV to share with teams and support data-driven decisions.

Settings / Admin Panel

Settings / Admin Panel

The settings panel lets admins configure alert thresholds, maintenance schedules, and user permissions. Role-based access ensures the right people see the right features. This area keeps the system flexible, secure, and tailored to each factory’s operational needs.

The settings panel lets admins configure alert thresholds, maintenance schedules, and user permissions. Role-based access ensures the right people see the right features. This area keeps the system flexible, secure, and tailored to each factory’s operational needs.

The settings panel lets admins configure alert thresholds, maintenance schedules, and user permissions. Role-based access ensures the right people see the right features. This area keeps the system flexible, secure, and tailored to each factory’s operational needs.

Results & Impact

Results & Impact

Results & Impact

Every minute of machine downtime meant revenue loss. Gold-Tech needed a system that improved reaction time, decision-making, and task transparency.

Every minute of machine downtime meant revenue loss. Gold-Tech needed a system that improved reaction time, decision-making, and task transparency.

Every minute of machine downtime meant revenue loss. Gold-Tech needed a system that improved reaction time, decision-making, and task transparency.

20%

Reduction downtime

25%

Higher shift productivity

24%

Faster dailly operator task

27%

Faster alert response time